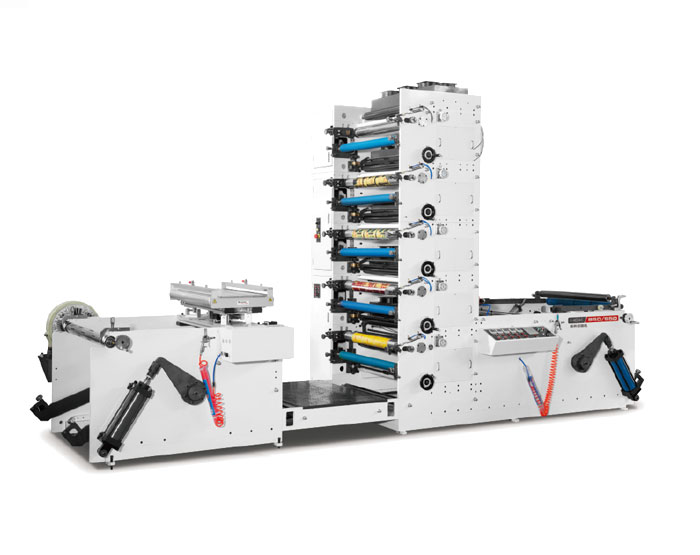

Unwinding and rewinding are controlled by magnetic brake and clutch;

With web guide;

Each station has one Ir dryer (UV dryer is optional);

The printing unit can register in 360 degrees;

The inking roller will be automatically off impression when press stop and rotate at lower speed in order to keep the ink from being drying;

Standard structure: one turn bar, one laminating, one die cutting stations;

Optional functions: varnish, cold foil, delam relam, slitting, conveyor.

For which products?

What is the thinnest thickness that can be printed?

What are the available widths?

What are the optional features?

GET A QUOTE