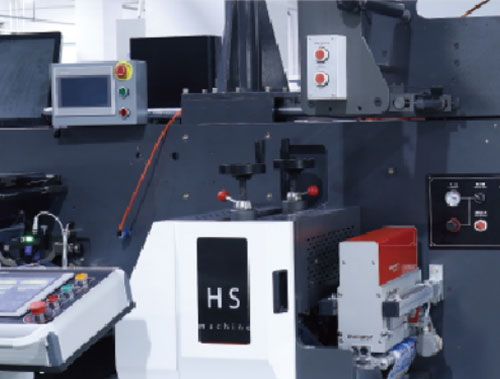

Label Flexo Printing Machine adopts the latest servo control and operation system, each unit has double servo motors. The machine is entirely controlled by servo. For each machine, there are 37 servo drivers, 12-color, 3 die cutting stations and conveving platform, ensuring high precision and stability during the machine runs in high speed.

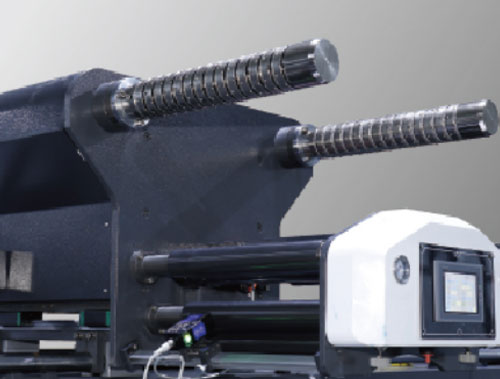

Printing roller adopts air support shaft sleeve system, stick sleeve or carving sleeve control by servolwithout gear). easy convenient and fast to change the sleeve. The printing cylindel without gear, which improved the printing quality and reduce the maintenance.

Printing and ink transfer pressure adjustment: printing roller adopt rolling pillow , only need to fine-tune the corresponding support frame on both side.When change new printing cylinder no need big adjustment, some special printing requirement also only need a little fine-tuning, the printing efficiency greatly improved.

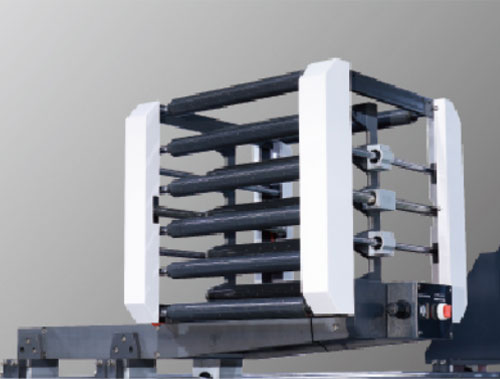

Anvil roller equips with water chiller, ensure not affect by UV curing temperature when printing film material.

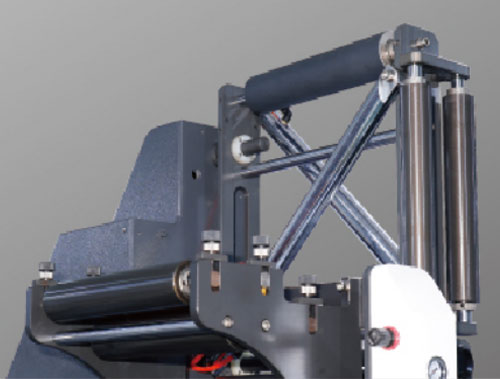

Unwinding unit equips with corona, dust, static electricity system, ensure the stability before printing

The printing process is equipped with a high-precision web guide and video monitoring equipment,providing highe assurance for label printing.

| Model | SFLEX-370 | SFLEX-450 |

| Maxmechanical speed | 200m/min | 200m/min |

| Max Printing width | 360mm | 450mm |

| Max.web width | 370mm | 460mm |

| Max.unwind diameter | 1050mm | 1050mm |

| Max.waste diameter | 900mm | 900mm |

| Max.repeat length | 241-610mm (76T-192T) | 241-610mm (76T-192T) |

| Loading method | Sleeve | Sleeve |

| Horizontal overprint adjustment | Motor driven | Motor driven |

| Vertical overprint control | Servo driven | Servo driven |

| Color Pre -register | Semi-Automatic | Semi-Automatic |

| Power supply | 380V/AC±10% | 380V/AC±10% |

| Fast changing ink system | Ink swift change | Ink swift change |

| Hot air drying | Optional | Optional |

| Cold foil (movable) | Optional | Optional |

| Turn bar (movable) | Standard | Standard |

| Overall dimensions (LxWxH) | 11m×1.5m×2.5m | 11m×1.68m×2.5m |

GET A QUOTE