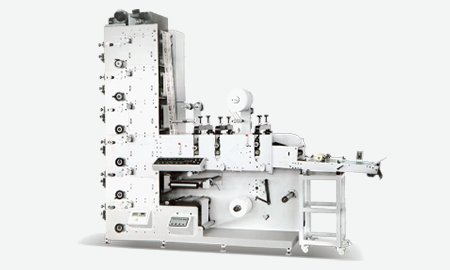

Flexo Printing Machine is a printing device based on the principle of roller printing. It achieves printing by transferring ink to the printing material under pressure. It uses a printing plate made of rubber or photosensitive resin, which can easily adapt to uneven printing surfaces, thus ensuring high-quality printing results.

So what is the difference between Label Flexo Printing Machine and Stack Flexo Printing Machine? In fact, there are certain differences in their functions, application scenarios and design features. The following is a detailed comparison of the two:

1. Label Flexo Printing Machine:

Focusing on the printing of labels, it can print labels of various sizes and shapes efficiently and accurately.

Usually equipped with advanced printing technology and control systems to ensure printing quality and accuracy.

It can be used to print barcodes, QR codes, text, patterns and other elements to meet the printing needs of different labels.

2. Stack Flexo Printing Machine:

Not only has printing function, but also emphasizes stacking design, which can handle stacking printing of large amounts of materials.

Suitable for continuous or intermittent printing operations, it can print large areas or long strips of materials.

In some models, it also has functions such as automatic feeding, receiving and waste recycling to improve production efficiency.

1. Label Flexo Printing Machine:

Widely used in label printing in food, medicine, daily chemicals, electronics and other industries.

Suitable for fast printing and customization of small batches and multi-variety labels.

In logistics, warehousing and other fields, it is also used to print various packaging labels and logos.

2. Stack Flexo Printing Machine:

Suitable for printing large areas of materials such as packaging materials, films, paper, plastics, etc.

Commonly used in packaging printing, advertising printing, promotional material production and other fields.

The stacking design makes it more advantageous when handling large amounts of materials and is suitable for large-scale production.

1. Label Flexo Printing Machine:

The structure is compact and easy to operate and maintain.

Usually equipped with precise control systems and sensors to achieve precise printing positioning and quality monitoring.

The choice of consumables (such as ink, label paper, etc.) is relatively wide to meet different printing needs.

2. Stack Flexo Printing Machine:

The stacking design enables it to have greater material handling capacity and can handle thicker or heavier materials.

The printing unit and stacking unit are usually designed independently and can be flexibly configured and adjusted as needed.

Equipped with automation devices to reduce manual operations, improve production efficiency and quality stability.

In summary, Label Flexo Printing Machine and Stack Flexo Printing Machine have their own advantages in functions, application scenarios and design features. When choosing, you should make comprehensive considerations based on specific needs and budget.

GET A QUOTE