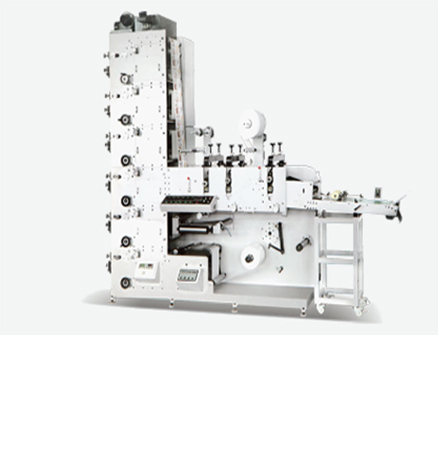

In the modern packaging and printing industries, the label folding machine plays a significant role. It is a device specifically designed for the efficient folding processing of various labels, boarding passes, scenic area tickets, and so on.

I. Working Principle and Core Technology

♦The label folding machine operates via a Human-Machine Interface (HMI) and is precisely controlled by a Programmable Logic Controller (PLC) that drives dual servo motors. This advanced control system ensures that the Label Folding Machine can maintain high-precision registration even during high-speed operation, making the position and size of the label folds accurate and error-free. For example, when processing logistics labels, it can precisely fold them according to the preset specifications, guaranteeing the consistency and standardization of the labels.

II. Functional Features

♦Versatility

It has functions such as slitting, counting, or automatic batch stop. This means that it can not only complete the folding task but also divide the labels according to requirements. At the same time, it can accurately count, and automatically stop when the set quantity or batch is reached, greatly improving production efficiency and management convenience.

♦Wide Applicability

It is suitable for a variety of materials. For example, models driven by dual servo motors can handle various films (PP, PVC, BOPP), shrink films, stickers, paper, aluminum foil, etc.; models driven by single servo motors can handle a variety of materials except shrink films. It can meet the diverse material needs of different industries for labels, whether it is food packaging labels or other product labels, it can be easily processed.

♦High Precision and Reliability

It is equipped with a high-definition fixed operation panel, which is convenient for operators to perform easy operations. At the same time, its modular unit design, such as the modular distinction of flexographic printing, die-cutting, unwinding and rewinding units, greatly improves production efficiency and precision. High-precision sleeves and advanced registration control technology ensure the accuracy of the label during the folding process, reducing errors and waste.

III. Application Fields

♦The label folding machine is an excellent auxiliary device for flexographic printing machines, flat die-cutting machines and rotary die-cutting machines. It is widely used in the folding equipment for inserted paper/leaflets in the logistics label and small item packaging market. For example, in the food industry, it is used for folding food packaging labels, ensuring that the labels are neatly and beautifully attached to the product packaging, enhancing the product image.

IV. Equipment Specifications and Optional Functions

♦Specification Sizes

There are various standard sizes such as 340mm, 370mm, 420mm, 450mm, 530mm, 650mm, etc., which can be adapted according to different production scales and label size requirements.

♦Rich Optional Functions

It provides a variety of optional functions such as cold foil stamping, die-cutting, conveying, multi-layer, varnishing, hot air drying, laminating, screen printing, etc. Enterprises can choose to add corresponding functions according to the special needs of their own products to achieve personalized customization of labels. For example, adding a cold foil stamping function can enhance the decorative effect of the label and attract consumers' attention.

In conclusion, with its advanced technology, rich functions and wide applicability, the label folding machine has become an indispensable important device in the label processing field, providing efficient and accurate solutions for product packaging and label application in various industries.

GET A QUOTE