Die-cutting machines play a crucial role in modern packaging production, being used across various industries to create custom packaging designs, labels, and more. Whether you are engaged in the food packaging, printing, or manufacturing business, choosing the right die-cutting machine can enhance your production efficiency, reduce costs, and improve the quality of your end products. The following will elaborate on the factors to consider when selecting a die-cutting machine in combination with the content of the document.

Die-Cutting Technology Principles and Applicable Scenarios

1.Rotary Die-Cutting

●Principle: It uses cylindrical dies mounted on a rotating roller for cutting.

●Applicable Scenarios: Suitable for large-scale production environments, capable of handling continuous runs of materials at high speeds. It has high precision for cutting thin materials such as paper, film, and self-adhesive labels, and is commonly used in applications like label cutting.

2.Flatbed Die-Cutting

●Principle: The flat die presses down on the material to cut it.

●Applicable Scenarios: Can handle a wider range of materials including cardboard, plastic, and laminated materials. It is especially suitable for cutting thicker packaging materials or performing detailed cuts, and is more cost-effective for small production runs.

Types of Die-Cutting Machines and Their Characteristics

1.Manual Die-Cutting Machines

●Advantages: Low cost and easy to use.

Disadvantages: Limited to low-volume and simple cuts, unable to meet the needs of large-scale packaging.

2.Digital Die-Cutting Machines

●Advantages: Use advanced software to cut designs without the need for physical dies, highly flexible. Suitable for short-run or prototype work, and ideal for companies that frequently customize their packaging designs.

●Disadvantages: Slower and less efficient for high-volume production compared to rotary or flatbed die-cutting machines.

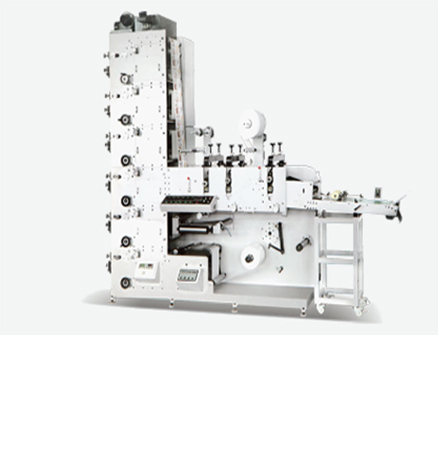

3.Rotary Die-Cutting Machines

●Advantages: Designed for high-speed production, suitable for large packaging operations. Highly precise and capable of continuous cutting.

●Disadvantages: Usually more expensive to purchase and operate due to the speed and advanced technology.

4.Flatbed Die-Cutting Machines

●Advantages: Can handle both thin and thick materials, suitable for various packaging types such as cartons and folding boxes. Capable of handling intricate designs and thick materials, and more affordable for smaller runs.

●Disadvantages: Slower than rotary die-cutting machines.

5.Laser Die-Cutting Machines

●Advantages: Offer extremely high precision without the need for physical dies, quick setup, and are suitable for intricate designs.

●Disadvantages: Higher initial cost and slower for thick materials compared to rotary or flatbed die-cutting machines.

Key Consideration Factors

1.Material Type

●Thin Materials: If your packaging materials consist of thin paper, plastic, or film, a rotary die-cutting machine may be the best choice.

●Thick Materials: If you work with thicker materials like cardboard or laminated packaging, a flatbed die-cutting machine offers more flexibility.

2.Production Volume

●Large-Scale Production: Rotary die-cutting machines are a better option due to their speed and continuous cutting capabilities.

●Small-Scale or Custom Projects: Flatbed or digital die-cutting machines may be more cost-effective.

3.Custom Design and Flexibility

●Frequent Changes in Packaging Design: If your business requires a high degree of customization, such as frequently changing packaging designs, digital or laser die-cutting machines are more suitable as they don't require physical dies and can quickly adapt to new designs.

Budget and Cost Considerations

Other Important Factors

♦Equipment Compatibility: Ensure that the die-cutting machine you choose is compatible with other equipment in your production line, such as printing machines, slitting machines, or laminating machines.

♦Die Maintenance and Longevity: Die-cutting tools and dies wear out over time. Rotary dies, in particular, need regular maintenance. Consider the availability and cost of replacement dies when choosing a machine.

♦Automation Features: Modern die-cutting machines come with automation features, such as auto-feed and waste removal systems, which can significantly improve efficiency and reduce labor costs.

♦Cost-Effectiveness of In-Line Systems: If your business also involves printing, consider an in-line system that integrates die-cutting with printing. Combining these processes in one workflow can save on space, reduce labor costs, and improve turnaround times.

GET A QUOTE