In the clothing industry, labels are not only the carrier of brand information, but also the extension of product quality and sustainable concepts. Labels of different substrates vary significantly in texture, durability, environmental protection and printing suitability. This article will explore the characteristics of common label substrates and their compatibility with flexographic printing technology to provide scientific material selection references for brands.

Clothing labels are identification carriers sewn or printed on clothing, usually located on the inside, collar or cuffs. They contain material composition, size specifications, washing and care instructions, safety categories, implementation standards, brand information, place of origin, etc. They have the functions of guiding consumers to purchase and properly care for clothing, complying with industry regulations, and conveying brand value. They are an important information medium connecting products and users.

Characteristics: natural fiber, breathable and skin-friendly, suitable for high-end clothing or brands that emphasize environmental protection.

Advantages: Biodegradable, in line with the concept of sustainability;Soft to the touch, suitable for labels that directly contact the skin (such as underwear, children's clothing).

Disadvantages: Easy to wrinkle, fade, and wear after multiple washings;Strong ink absorption, high-precision printing technology is required to avoid smudging.

Flexo printing adaptability: The surface of cotton is rough, and high-viscosity inks are required for flexographic printing. It is suitable for monochrome or simple designs, and the expression of complex patterns is limited.

Features: synthetic fiber, high strength, wear resistance, widely used in sportswear and outdoor clothing labels.

Advantages: Wrinkle-resistant, washable, excellent color durability; Smooth surface, suitable for high-resolution pattern printing.

Disadvantages: Non-degradable, environmental controversy; Easy to shrink and deform at high temperature.

Flexo printing adaptability: Polyester has a smooth surface and good compatibility with water-based inks. Flexographic machines can efficiently complete multi-color overprinting, suitable for mass production.

Features: lightweight, wear-resistant and elastic, often used in high-end clothing or functional clothing.

Advantages: Tear-resistant, suitable for label positions that need to be stretched repeatedly; Strong surface gloss, improves label texture.

Disadvantages: High cost; Poor hygroscopicity, easy to breed odor in humid environments.

Flexo printing adaptability: Special inks (such as UV curing inks) are required, and the flexographic machine needs to adjust the pressure to avoid material deformation.

Features: Made of pressed polypropylene fibers, lightweight and low-cost, commonly seen in fast fashion brands.

Advantages: Breathable, moisture-proof, suitable for disposable or short-term labels; Recyclable, some materials support biodegradation.

Disadvantages: Low strength, easy to break; Loose surface fibers, easy to blur printed details.

Flexo printing adaptability: Low viscosity inks must be used to avoid penetration; suitable for simple text or LOGO printing.

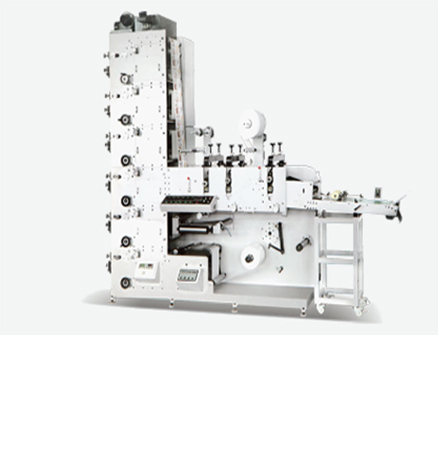

Label Flexo Printing Machine brush has become one of the mainstream technologies for label printing due to its high efficiency, low consumption and environmental protection:

Adaptability: Good at processing smooth substrates such as polyester and synthetic paper, supporting high-speed continuous printing;

Environmental protection: Water-based ink has low VOCs emissions and meets European and American environmental protection standards;

Limitations: The ability to restore details on rough surfaces such as cotton cloth and coarse grain non-woven fabrics is weak, and it needs to be combined with pre-coating technology.

The selection of label substrates needs to take into account aesthetics, function and responsibility, and flexographic printing technology provides a reliable path for the synergy of environmental protection and efficiency.

GET A QUOTE