In the field of modern printing, flexographic printing occupies an important position with its unique charm and advantages. It has a profound historical origin and shows strong vitality in continuous technological innovation. Understanding the technology and history of flexographic printing will open a window for us to understand the development of the printing world.

I. Introduction

Flexographic printing, as an important member of modern printing technologies, plays a crucial role in fields such as packaging, labels, and publications with its unique advantages. It not only has efficient production capacity but also can achieve high-quality printing effects. Understanding the technical characteristics and historical development of flexographic printing helps us better recognize the value and significance of this printing method.

II. Technical Characteristics of Flexographic Printing

(1)Printing Principle

Flexographic printing uses a flexible printing plate. Ink is transferred to the printing plate through an anilox roller and then transferred to the substrate. The printing plate of this printing method has the characteristics of being soft and bendable, which can adapt to the surfaces of substrates of different shapes and achieve wide printing applicability.

(2)Ink Characteristics

The ink used in flexographic printing usually has the characteristics of quick drying and being environmentally friendly. Quick-drying ink can increase printing speed, reduce drying time, and meet the needs of high-speed production. At the same time, environmentally friendly ink meets the requirements of modern society for green printing and reduces environmental pollution.

(3)Color Performance

Flexographic printing can achieve rich color performance. Through precise color management and blending, vivid and realistic color effects can be printed. Moreover, flexographic printing also has good expressiveness for spot colors and can meet customers' needs for specific colors.

(4)Printing Precision

Although flexographic printing may not be as precise as other printing methods such as offset printing in some aspects, with the continuous progress of technology, the precision of flexographic printing is also constantly improving. Modern flexographic printing equipment can achieve high register precision and resolution, meeting the quality requirements of most printed products.

III. Historical Development of Flexographic Printing

(a.)Origin and Early Development

The history of flexographic printing can be traced back to ancient seal and rubbing techniques. As time goes by, these techniques gradually evolved and developed, laying the foundation for the birth of flexographic printing.

At the end of the 19th century and the beginning of the 20th century, flexographic printing began to emerge as an independent printing method. At that time, flexographic printing was mainly used for packaging and label printing and was welcomed by the market for its simplicity and speed.

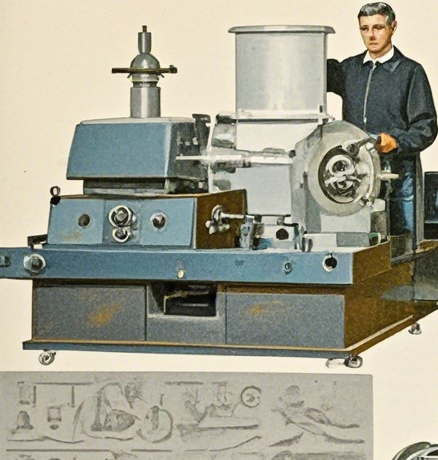

In the middle of the 20th century, with the progress of material science and mechanical manufacturing technology, flexographic printing ushered in major technological innovations. The emergence of new printing plate materials, inks, and printing equipment has greatly improved the quality and production efficiency of flexographic printing.

For example, the invention of photopolymer plates has made the production of flexographic printing plates more simple and precise. At the same time, the emergence of high-speed printing equipment has enabled flexographic printing to meet the needs of large-scale production.

(b.)Modern Applications and Future Prospects

Entering the 21st century, flexographic printing has achieved greater development in technology and applications. With the application of digital technology, flexographic printing has achieved integration with digital production processes, further improving production efficiency and quality control levels.

In the future, flexographic printing is expected to continue to play its advantages and continuously expand its application scope in fields such as packaging, labels, and publications. At the same time, with the continuous improvement of environmental protection requirements, the environmental protection characteristics of flexographic printing will make it occupy a more important position in the field of green printing.

IV. Conclusion

As a printing method with a long history and unique technical advantages, flexographic printing plays an important role in the modern printing industry. Through continuous technological innovation and development, flexographic printing will continue to provide high-quality and efficient printing solutions for various industries and contribute to promoting economic development and cultural dissemination.

GET A QUOTE