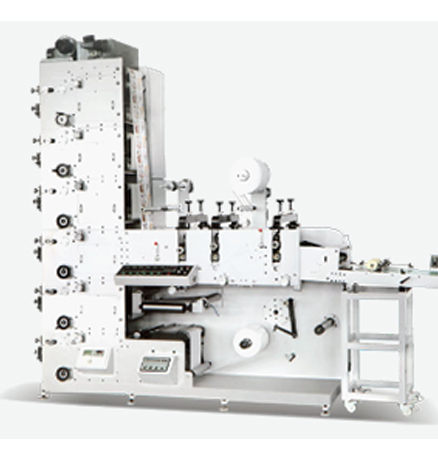

Currently in the printing industry, Stack Flexo Printing Machine is available. In-depth analysis of the book's effects and benefits, the key points of mastering, and the new edition of the book's new edition to help India develop its skills.

I. Equipment Investment Costs

Purchase Price of the Machine: The prices of Stack Flexo Printing Machines vary significantly depending on the brand, model, and configuration. Generally speaking, the price of a basic model may range from several hundred thousand yuan, while high-end models equipped with more advanced functions, higher printing precision, and speed can cost over one million yuan. For example, a standard model of a well-known brand's stack flexo printing machine is priced at around 600,000 yuan, while its high-end version equipped with an automated color management system and high-speed printing components is priced as high as 1.5 million yuan.

Costs of Supporting Equipment and Installation: Besides the machine itself, the costs of supporting equipment also need to be considered, such as ink supply systems, drying devices, and plate-making equipment. The combined costs of these supporting equipment may account for 30% - 50% of the purchase price of the machine. In addition, professional personnel are required for the installation and commissioning of the equipment, and the installation cost is usually around 50,000 - 100,000 yuan, depending on the complexity of the equipment and the conditions of the installation site.

II. Operating Costs

Cost of Ink Consumption: Ink is the main consumable in the printing process. The ink consumption of Stack Flexo Printing Machines depends on factors such as the printed patterns, the number of colors, and the printing area. Generally, the cost of ink per square meter of the printed area ranges from 5 to 20 yuan. For example, when printing large areas of solid colors on packaging materials, the ink consumption is relatively high, which may reach about 15 yuan per square meter. When printing simple lines or text on labels, the ink cost may be reduced to 8 yuan per square meter.

Cost of Electricity Consumption: The printing machine consumes a certain amount of electricity during operation. Its power usually ranges from 10 to 50 kilowatts, and the specific power consumption depends on the printing speed and the load of the machine. Calculated at 1 yuan per kilowatt-hour, if the average power of the machine is 20 kilowatts, it operates for 8 hours a day and 22 days a month, then the monthly electricity cost is approximately 3,520 yuan.

Cost of Material Loss: There may be certain losses of the substrate materials during the printing process, such as cutting waste of paper, stretching and deformation of plastic films, etc. The material loss rate is generally between 5% and 15%. For example, when printing a batch of packaging materials worth 100,000 yuan, if the material loss rate is 10%, the cost of material loss will reach 10,000 yuan.

Labor Cost: Operating the Stack Flexo Printing Machine requires a certain number of professional personnel, including the machine operator and assistants. Labor costs vary depending on the region and the experience of the personnel. Generally speaking, the monthly salary of a machine operator is between 8,000 and 15,000 yuan, and that of an assistant is between 4,000 and 8,000 yuan. If a machine is equipped with one operator and one assistant, the monthly labor cost will be around 12,000 - 23,000 yuan.

III. Economic Benefits

Benefits Brought by the Improvement of Production Efficiency: Stack Flexo Printing Machines have a relatively high printing speed and can print dozens or even hundreds of meters of substrate materials per minute. Compared with traditional printing equipment, its production efficiency has been greatly improved. For example, a packaging and printing enterprise could only produce 10,000 packaging products per day with its old equipment. After using the stack flexo printing machine, the daily output can be increased to 30,000, which greatly shortens the order delivery time and enables the enterprise to take on more orders and increase its revenue.

Added Value Brought by the Improvement of Printing Quality: This machine can achieve high printing resolution, accurate overprinting precision, and excellent color reproduction, which significantly improves the quality of printed products. High-quality printed products can add value to the enterprise's products and enhance their competitiveness in the market. For example, in the printing of cosmetic packaging, the exquisite printing effect can attract consumers' attention, make the products more attractive, and thus promote sales and improve the profit margin of the products.

Benefits Created by Versatility and Flexibility: Stack Flexo Printing Machines can adapt to various substrate materials and different printing requirements and can implement multiple printing processes on the same machine, such as normal printing, anti-counterfeiting printing, and varnishing. This versatility and flexibility enable enterprises to meet the diverse needs of different customers, expand their business scope, and enter more niche markets, bringing more profit-making opportunities for enterprises. For example, a printing enterprise has successfully entered multiple fields such as food packaging, pharmaceutical packaging, and electronic label printing by taking advantage of the versatility of this machine. The enterprise's market share has been continuously expanding, and its economic benefits have been significantly improved.

GET A QUOTE